Rotor Performance Upgrades

REC offers a variety of rotor performanceu upgrades to give your engine the edge in both performance and reliability tuning.

CNC Porting

If you are an engine builder or do enough building to where you commonly use a specific type of intake porting, REC can scan and digitize your port configuration and convert this into a CNC program. Once this is complete, this CNC equipment can produce exact duplicates on all your future engine porting. Some touch ups and polishing may be required. Please inquire for pricing details.

Combustion Chamber Machining

Although recently new technology, combustion chamber modifications not only provide the allowance of reducing compression but give us the availability to reshape the combustion chamber bathtub and make all the combustion chambers identical and equal in size. By doing so you end up with a perfectly symmetrical rotor and exact and matching engine displacement on all combustion faces. This not only provides for uniform and even combustion pulses, but an equally even and cleaner burn which can be better for more accurate tuning. Although this CNC process can be performed on just about any rotor, best results are noticed on pre-89 rotors which have more material from the factory. A substantial weight reduction is also gained and rebalancing the rotor is strongly recommended. The most common application are engines fitted with 87 to 88 turbo rotors which are built for high power and high boost pressures. In theory this increases the displacement of the engine and reduces the chance of detonation. When lightened, this generation of turbo rotor is an excellent choice as a direct replacement for the more fragile 93 up and 20B rotors. The 87-88 turbo rotor is much more robust and durable due to its overall mass. Again, once lightened, this rotor will weigh about the same or slightly less than a factory 93 up or 20B rotor.

Cost per rotor: $220.00

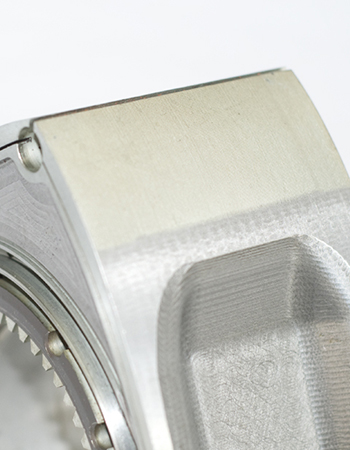

Please see our before and after photos below. *After images below also have rotor clearance and lightening modifications in addition to the combustion chamber modifications.

Before

After

Rotor Clearancing

REC offers three different types of rotor clearancing.

Face Clearancing

This type of clearancing is typically for aggressive street use or road racing. This method entails removing a determined amount of material from the gear side and the non-gear side of the rotor along with an equal amount of material from the gear itself and the hardened center surface on the opposite side. Recommended for sustained high temperatures and higher rpm applications.

Cost: $80 per rotor

Tip Clearancing

This type of clearancing is more commonly used in engines which undergo greater loads and create more horsepower and torque. High boost applications and drag racing engines will benefit from this method as the circumstances yield higher chances of crank shaft deflection. Because the tip of the rotor is the furthest away from the centerline of the crankshaft it becomes the most likely spot to contact the side housings.

Cost: $60 per rotor

Race Clearancing

This type of clearancing is a combination of the two above procedures. Because it is common in engines making continuous power and rpm for the rotor gear or tips to contact the side housings, the best overall protection is noticed by performing this modification. Because the rotor itself only has to be set up and installed on the machine ones to perform both procedures we package the total cost to benefit the customer.

Cost: $125 per rotor

Rotor Lightening

All lightening processes are carried out on CNC equipment and is a very safe and accurate method used to reduce the overall weight of the rotating assembly. Although different types of rotors are subject to different amounts of material removed, one quarter of a pound all the way to a full pound of weight can be accurately removed. Further weight reductions can be achieved when we also perform our Combustion Chamber Modifications noted above.

Some advantages to ligtening include:

- Smoother power band

- Quicker turbo spool time

- Less change of vibration

- Less wear on bearings

- Better heat dissipation into motor oil

- More accurately balanced rotating assembly.

Any rotor which is lightened will require the rotor to be rebalanced on it's own axis.

Cost range: $155.00-350.00 per rotor.

Cost to dynamically rebalance rotor: $80.00 per.

Before

After

Rotor Gear Locking

Essential for any high rpm or high boost application, locking your rotary gears provides optimal reliability and strength. The factory rotary gears are retained with either a 9 or 12 spring steel roll pins. All of the pre-1985 rotors utilize only nine pins and become the more likely candidates to suffer from "gear walking". Even though the 1986 and later rotors utilize three more spring pins for a total of 12 pins, we have seen "gear walking" in several instances.

Gear Walking is a condition where the rotor gear gradually pulls away from the body of the rotor under heavy load or high rpm conditions. REC has developed a method to reliably retain these gears in their intended position restricting them from ever walking away from the rotor.

The other benefit when performing this modification is that the gear can be easily removed and reinstalled after REC has performed the initial work. The factory design of the "press fit" and spring pin retained gear is very difficult to remove and special equipment is required. In short, we remove the old design, transform to our design and the gear can be either service or replaced in the future using conventional hand tools.

Cost: $165.00